Printing Process of Paper Tube/Paper Cans/Paper Canisters' Label

Jun 18, 2021

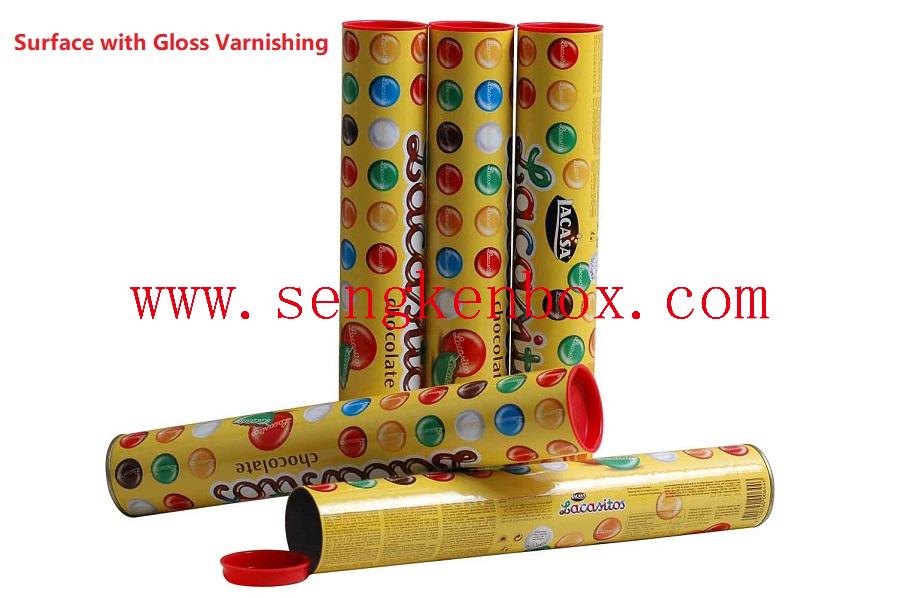

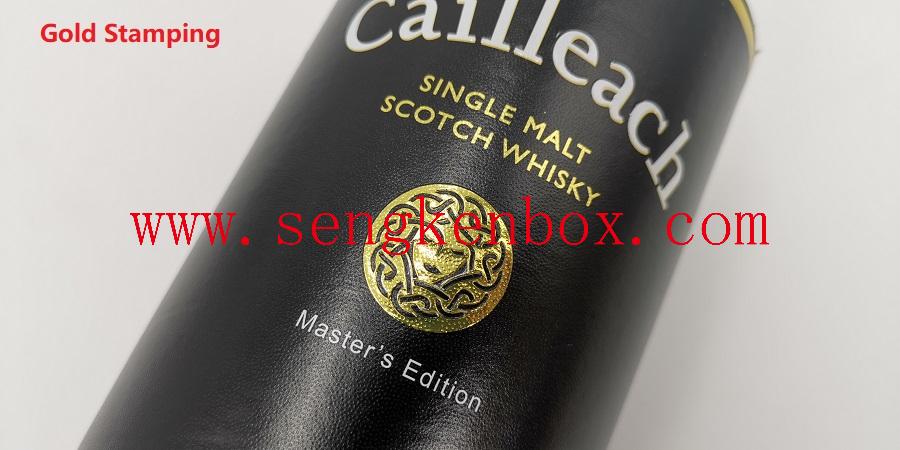

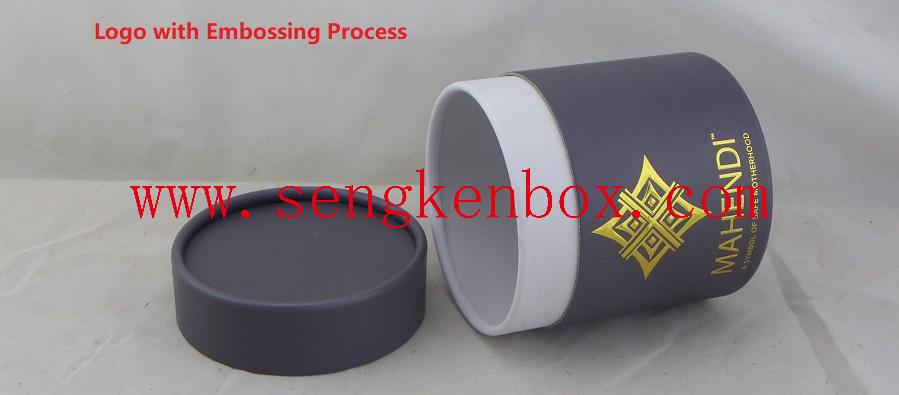

For printing process of paper tube/paper cans/paper canister's labels, there are Glazing/Glossy Varnishing/Matte Lamination,UV Coating,Hot Stamping Process and Embossing Process.

1.Glazing/Glossy Varnishing/Matte Lamination : It can not only enhance the surface brightness and protect the printed graphics, but also does not affect the recycling of paper, which can save resources and protect the environment. Therefore, it is widely used in the surface technology of paper tube,paper cans,and paper canister packaging.

2.UV coating:The UV process is applied in the paper tube/paper cans/paper canister packaging industry. Its process characteristics are: on the surface of ordinary offset paper or BOPP dumb film, the screen printing process is used to coat the paper pattern to make the coating area. It forms a strong contrast with the matte or bright surface, and achieves the finishing touch to the graphics and texts that need to be emphasized: local UV, crystal embossing, colorful, matte, etc.

3.Hot Stamping: In the fierce market competition, in order to increase the added value of products and more effectively prevent counterfeiting of packaging, more and more packaging paper cans use hot stamping technology. Anodized aluminum hot stamping foil mainly uses heat and pressure to transfer the pattern or text to the surface of the hot stamped material. The characteristics of finished bronzing: the pattern is clear, beautiful, and the colors are diverse and dazzling. The bronzing on the paper tube/paper can packaging can play a role in beautifying the product that highlights the design theme.Colors can be OEM as per customer's request.

4.Embossing Process:The protruding process mainly uses pressure to transfer the pattern to the surface of the material. The embossing effect is produced by the embossing process, and the paper tube/paper cans/paper canister packaging is more beautiful, the theme is more vivid, and the touch is richer.

All packagings can be OEM as per your request.

We have been in packaging industry for more than 20 years.As our valued customer, we hope that we can help you save time, money and stress when it comes to finding your affordable and dependable packaging for your products. Feel free to contact us if you have any questions or concerns!