Brand:

SengKenItem NO.:

SKM-BOrder(MOQ):

1Payment:

50%T/T in advance, balance paid again when fiMarket Price:

$500000Price:

$500000Product Origin:

CNColor:

SilverShipping Port:

Hangzhou or ShanghaiLead Time:

90daysWeight:

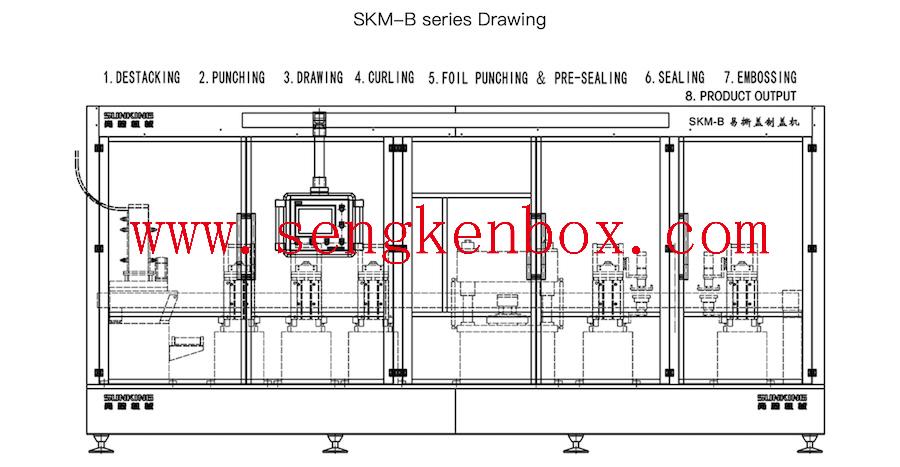

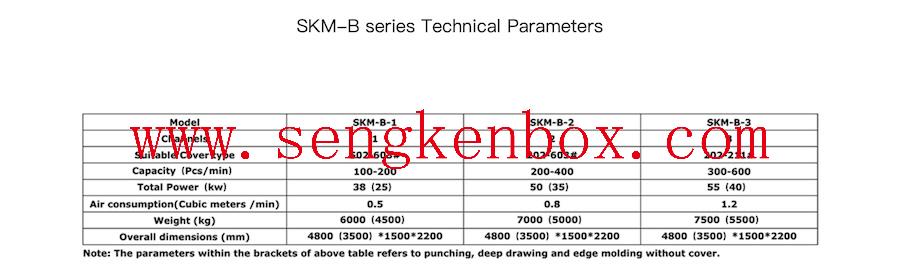

7500This series machine can be used to manufacture 202-603# POE,and specially suitable for bigger 307-603# POE. It is automatically complete the functions of shell feeding, punching, deep drawing, crimping, aluminum foil pre-sealing, sealing, embossing and output etc. Independent servo controls each function module, adjusts parameters separately, and achieves high speed response and synchronous movement. Inclined punching arrangement makes the aluminum foil waste least. We can make any new model according to clients’ requirement. All the informations for reference only,The products are subject to change without notice.

SKMB-401G high-speed easy-tear cover production equipment

It is a special equipment used for bonding new retort aluminum foil easy-to-tear lids. The machine automatically completes loop placement, punching, pre-bending, curling, preheating, punching aluminum foil positioning, heat sealing, handle alignment/dispensing/folding , cooling, flattening or embossing, output and other actions. Each piece of equipment adopts a servo modular design, a synchronous belt-driven handling method, and is equipped with 2 channels.

Main technical parameters of each device:

(1) Production speed: 80-120 pieces/minute for one channel, 160-240 pieces/minute for two channels in total (different sealing materials, basic cover materials, etc., different speeds).

(2) The sealing pass rate of each machine: ≥99% (provided that the aluminum foil and cover ring are qualified)

(3) Power of each complete machine - two channels: power consumption is about 20-30KW (total installed power is about 60KW)

(4) Power supply for each unit: 3N 50Hz 380V (three-phase five-wire)

(5) Air source pressure of each unit: ≥ 0.6Mpa

(6) Compressed air consumption per unit: about 0.4M³/min,

(7) Cooling water flow rate of each unit: about 33L/min, cooling capacity 5P, pressure 0.4MPa

(8) Dimensions of each unit: approximately 5000mm×3700mm×2200mm for two channels (see attached picture))

(9) Weight of each complete machine: about 7500Kg

Related Tags :

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.